Essential Propeller Parts and Hubs for Optimal Marine Performance

What is a Marine Propeller?

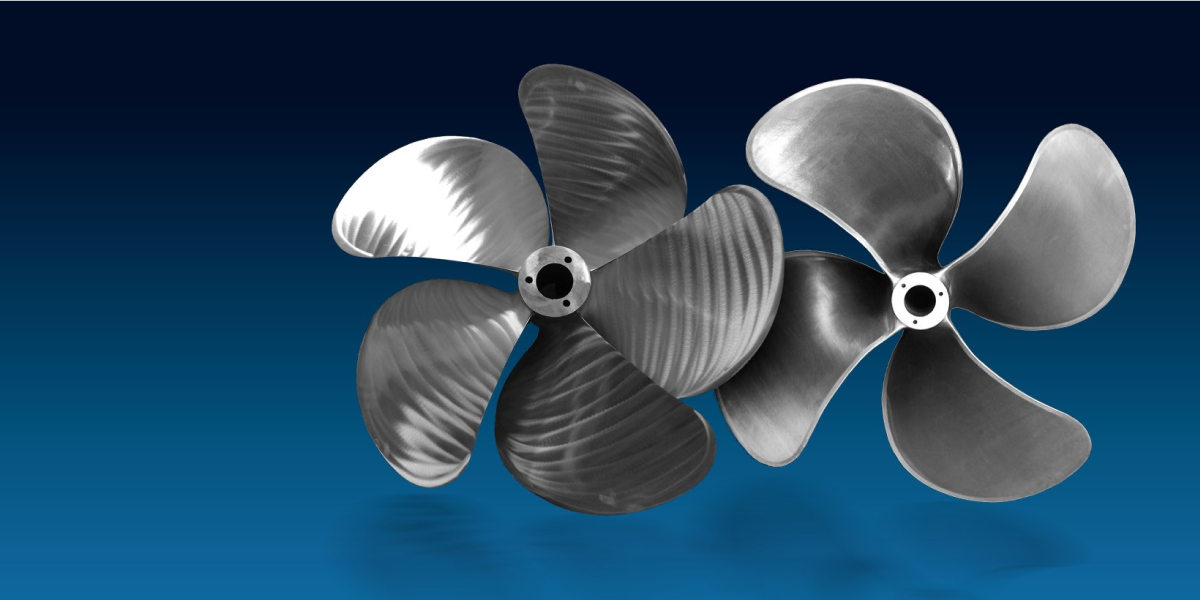

A marine propeller is a device with rotating blades that generate thrust by displacing water, allowing the boat to move forward or backward. Each part of the propeller is designed to achieve specific functions, from maximizing thrust and minimizing cavitation to ensuring a secure attachment to the propeller shaft. The propeller hub, blades, and other parts work together as an integrated system that converts engine power into motion efficiently.

Why Propeller Parts Matter for Marine Performance

Key Propeller Parts and Their Functions

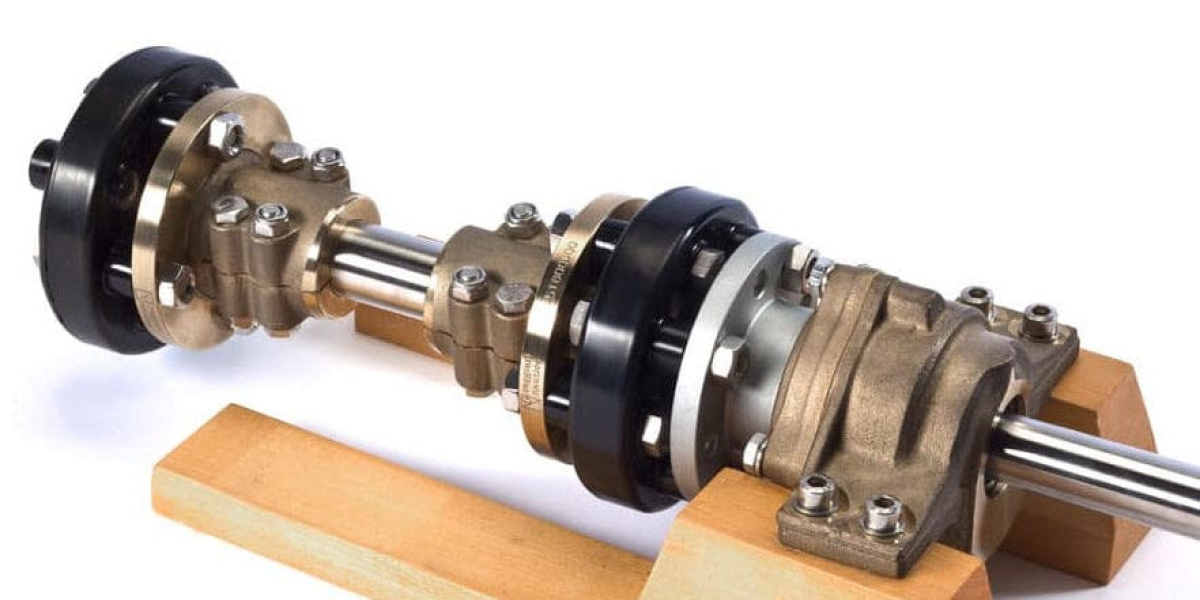

1. Propeller Hub

The propeller hub is the central part of the propeller that connects to the engine’s shaft. It holds the blades in place and transmits engine power from the shaft to the water via the blades.

Functions of the Propeller Hub:

- Attachment to the Shaft: The hub connects the propeller to the engine shaft, ensuring the secure transfer of power.

- Blade Support: It provides structural integrity, holding the blades in place.

- Vibration Dampening: The hub often incorporates a rubber or plastic bushing that helps absorb vibrations and reduce the risk of propeller damage.

Types of Propeller Hubs:

- Fixed Hub: Commonly found on single-piece propellers, a fixed hub directly attaches to the shaft.

- Interchangeable Hub: This hub design allows for easy removal and replacement, making it ideal for vessels that frequently change propellers to suit different operating conditions.

- Rubber Hub (Press-Fit): This type of hub contains a rubber sleeve between the propeller and hub, which dampens vibrations and provides protection in the event of sudden impacts.

2. Propeller Blades

The blades are the most visible part of the propeller and are responsible for generating thrust by displacing water. The number of blades, blade shape, and pitch angle are crucial factors that affect a vessel’s speed, fuel efficiency, and maneuverability.

Blade Components and Terminology:

- Leading Edge: The front edge of the blade that first contacts the water.

- Trailing-Edge: The rear edge of the blade that leaves the water.

- Face: The side of the blade that faces forward and pushes against the water to generate thrust.

- Back: The opposite side of the blade, facing aft.

Key Blade Parameters:

- Pitch: The distance a propeller would theoretically move forward in one revolution. Higher-pitch propellers are suited for faster speeds, while lower pitch propellers are better for slow, powerful movement.

- Diameter: The diameter of the propeller, which affects thrust and is determined by the vessel’s engine power and operational requirements.

- Rake: The angle of the blades relative to the hub, affecting lift and cavitation control.

3. Propeller Shaft

The propeller shaft connects the engine to the propeller hub, transmitting rotational power from the engine to the propeller.

Key Considerations for the Propeller Shaft:

- Material: Marine-grade stainless steel is commonly used for its strength and corrosion resistance.

- Alignment: Proper shaft alignment is crucial to minimize vibration and ensure efficient power transfer.

- Diameter: The diameter must match the engine’s torque and horsepower requirements to prevent excessive wear.

4. Thrust Washer

The thrust washer sits between the propeller hub and the shaft, distributing the load from the propeller to the shaft. It prevents damage to both the hub and the shaft by reducing friction.

Benefits of the Thrust Washer:

- Reduces frictional wear on the propeller hub and shaft

- Distributes thrust forces evenly, preventing damage to the engine and transmission

- Provides a stable surface for the propeller to rotate efficiently

5. Propeller Nut and Cotter Pin

Optimizing Propeller Performance

Choosing the Right Propeller Hub and Parts for Your Vessel

- Consider Vessel Type and Usage: For high-speed vessels, choose propellers with larger diameters and higher pitch, while workboats benefit from propellers with a lower pitch for better thrust at low speeds.

- Match Material to Environment: Stainless steel hubs and blades offer excellent durability and corrosion resistance, making them ideal for saltwater environments.

- Balance Thrust and Efficiency: Choosing the right number of blades and pitch can help achieve the perfect balance between speed and fuel efficiency.

- Prioritize Flexibility with Interchangeable Hubs: For vessels that operate in varying conditions, interchangeable hubs make it easy to switch propellers, optimizing performance for each mission.

Regular Maintenance for Longevity

Selecting a Reliable Supplier for Propeller Parts

Choosing a trusted supplier for propeller hubs, blades, and other parts ensures that you receive high-quality components that can withstand demanding marine environments. A reputable supplier should offer:

- High-quality materials suited to marine conditions, such as stainless steel and bronze.

- Technical support to help select the best propeller parts for your specific vessel type and operating conditions.

- Custom solutions for specialized applications, allow you to optimize performance based on your vessel’s requirements.

Upgrade Your Marine Propeller with High-Performance Parts and Hubs

Achieve optimal marine performance by selecting high-quality propeller hubs and parts designed for durability and efficiency. Whether you need a complete propeller assembly or individual parts, we provide precision-engineered solutions for marine applications. [Contact us today to discuss your vessel’s needs and find the ideal propeller solution.]

FAQ's

The propeller hub connects the propeller to the shaft, transmitting power from the engine to the propeller blades and providing structural support for efficient thrust generation.

Consider factors like vessel type, desired speed, and usage. A higher pitch is suitable for high-speed applications, while a lower pitch provides more thrust for workboats and slower-moving vessels.

The thrust washer reduces friction between the propeller hub and shaft, distributing load evenly to prevent damage and ensure smooth operation.