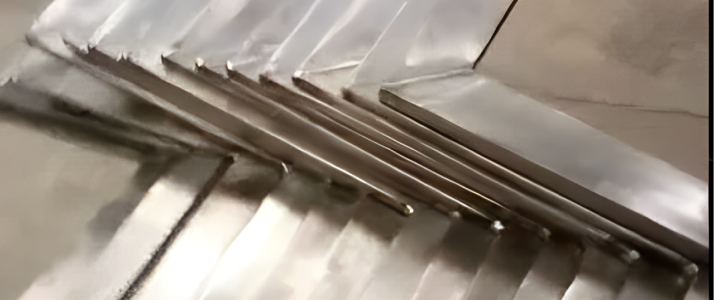

Copper Titanium Hangers

Need any Help?

Feel free to contact us any time. we will get back to you as soon as we can!

DOWNLOAD OUR BROCHURE

CONTACT US

At Marine Techq, we specialize in solutions for the demanding marine environment. While copper-titanium hangers’ true application lies in a very different arena, industrial processes involve electrolysis.

What are Copper-Titanium Hangers?

Copper-titanium hangers are specialized conductive bars used within electrolytic cells. These cells utilize electricity to drive chemical reactions. Copper-titanium hangers serve two crucial purposes:

- Current Conduction:

The core of the hanger is typically made of copper, an excellent conductor of electricity.

- Corrosion Resistance:

Titanium offers exceptional resistance to the harsh chemicals and corrosive environments present in electrolysis processes.

Why Use Copper-Titanium Hangers?

There are several advantages to using copper-titanium hangers in electrolysis:

Superior Conductivity:

Copper ensures efficient current flow within the cell, maximizing the effectiveness of the electrochemical reaction.

Enhanced Durability:

The titanium cladding protects the copper core from corrosion, extending the lifespan of the hanger and reducing maintenance needs.

High Strength:

Titanium provides structural integrity to the hanger, allowing it to withstand the physical demands of the electrolytic process.

Continue Reading on Similar Topics:

Applications of Copper-Titanium Hangers

Copper-titanium hangers find use in various industrial electrolysis applications, including:

- Electroplating:

This technique uses electricity to deposit a thin layer of metal onto a conductive surface. Copper-titanium hangers efficiently conduct current within the electroplating bath.

- Metal Winning:

Electrolysis is used to extract certain metals from their ores. Copper-titanium hangers ensure efficient current transfer during the extraction process.

Advanced Copper-Titanium Hangers

At Marine Techq, we are proud to offer our state-of-the-art Copper-Titanium Hangers, a superior choice for applications demanding high strength, exceptional corrosion resistance, and prolonged durability. These hangers combine the best properties of copper and titanium, providing an innovative solution that stands up to the most challenging environments.

Key Features:

- Enhanced Strength and Durability: Our Copper-Titanium Hangers are designed to bear heavy loads while resisting wear and tear, making them ideal for both industrial and marine environments.

- Corrosion Resistant: The unique alloy composition provides excellent resistance to corrosion, significantly extending the life of your installations under harsh conditions.

- Lightweight Design: Enjoy the benefits of a material that reduces overall weight without compromising on strength, facilitating easier installation and handling.

- Customizable Solutions: Tailored to meet your specific requirements, our hangers are available in various sizes and specifications to suit your unique project needs.

Why Choose Marine Techq’s Copper-Titanium Hangers?

- Innovative Material Technology: Our commitment to research and development in metal alloys allows us to provide products that lead the market in performance and reliability.

- Precision Manufacturing: Each hanger is crafted with meticulous attention to detail, ensuring flawless quality and performance.

- Comprehensive Support: Marine Techq’s team of experts is ready to assist you from selection through to installation, ensuring that you get the most out of our products.

FAQ

What are some advantages of copper-titanium alloys?

Copper-titanium alloys offer several advantages :

Increased Strength: Titanium additions significantly enhance the strength of copper, making it suitable for applications requiring higher load-bearing capacity.

Improved Corrosion Resistance: While copper offers decent corrosion resistance, titanium provides even better protection, especially against saltwater corrosion, making the alloy valuable in marine environments.

Increased Strength: Titanium additions significantly enhance the strength of copper, making it suitable for applications requiring higher load-bearing capacity.

Improved Corrosion Resistance: While copper offers decent corrosion resistance, titanium provides even better protection, especially against saltwater corrosion, making the alloy valuable in marine environments.

What are the industrial applications that utilize copper-titanium?

Copper-titanium finds applications in various sectors. Here are two examples:

Aerospace: Due to its lightweight nature and high strength, copper-titanium can be used for aerospace components requiring a balance of weight and durability.

Electrical Engineering: The good electrical conductivity of copper, combined with the corrosion resistance of titanium, makes this alloy suitable for specific electrical components.

Aerospace: Due to its lightweight nature and high strength, copper-titanium can be used for aerospace components requiring a balance of weight and durability.

Electrical Engineering: The good electrical conductivity of copper, combined with the corrosion resistance of titanium, makes this alloy suitable for specific electrical components.

Are there different grades of copper-titanium?

Yes, there are various grades of copper-titanium available, each with slightly different properties. The specific ratio of copper to titanium, along with any additional elements, will influence factors like strength, conductivity, and workability. At Marine Techq, we can help you identify the most suitable grade for your specific application.

What are the applications of copper-titanium in marine engineering?

Copper-titanium's high conductivity and corrosion resistance make it valuable in marine engineering for components like seawater piping and heat exchangers.