Customized CNC

Machined Inconel

Need any Help?

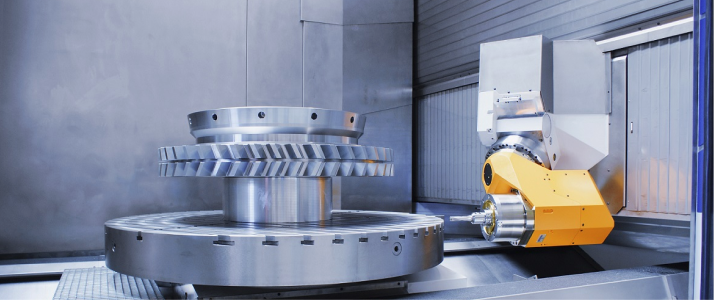

At Marine Techq, we redefine precision through our CNC machining processes, ensuring that each Inconel component meets the highest standards of accuracy and reliability. Our commitment to customization allows you to tailor the machining process to your exact specifications, offering a spectrum of options, including size, dimensions, surface finish, tolerance levels, and complex geometries.

Whether you require components for the aerospace industry, chemical processing applications, or precision parts for oil and gas, our Customized CNC Machined Inconel delivers versatility and performance. The material’s superior resistance to corrosion and high-temperature environments makes it an ideal choice for critical applications where reliability is non-negotiable.

Dive into a world where precision meets strength, and customization knows no bounds. Our CNC-machined Inconel components find their place in the forefront of innovation, contributing to the success of projects demanding the highest quality materials. Choose Marine Techq for precision, durability, and a tailored approach to CNC machining with our Customized CNC Machined Inconel.

Key Features

- Material Excellence

- Precision Engineering

- Customization Options

Continue Reading on Similar Topics:

Specifications for Customized CNC Machined Inconel

| Form | Standard |

| Metal Type | UNS N06625 |

| Bar | ASTM B446 AMS 5666 BS3076 |

| Wire | AMS 5837 |

| Sheet | ASTM B443 AMS 5599 BS3072 |

| Plate | ASTM B443 AMS 5599 BS3072 |

| Pipe | ASTM B444 ASTM B704 AMS 5581 BS3074 GE B50TF133 |

| Tube | ASTM B444 ASTM B704 AMS 5581 BS3074 GE B50TF133 |

| Fitting | ASTM B366 Din 17754 |

| Forging | |

| Weld Wire | |

| Weld Electrode | |

| NA 21 | All forms |

| Din | 2.4856 |

Types of Customization

- Size and Dimensions

- Surface Finish

- Tolerance Levels

- Complex Geometries

Types of Inconel Alloys

- Inconel 600

- Inconel 625

- Inconel 718

Charts

Surface Finish Options Chart

| Ultimate Tensile | Yield Strength ( 0.2 % OS ) | Elong . in 2 in . or 50mm or 4D , min . , % | R / A | Hardness | |

|---|---|---|---|---|---|

| Cold Worked / SR Over 1 (25.4 ) to 3 | |||||

| Min | 120 KSI | 60 KSI | 30 | ||

| Max | |||||

| Min | |||||

| Max | |||||

| Hot Worked / Annealed | |||||

| Min | 120 KSi | 60 KSi | 30 | ||

| Max | |||||

| Min | |||||

| Max |

Chemical requirements

| Ni | Mn | Si | Fe | AI | S | C | |

|---|---|---|---|---|---|---|---|

| Max | 1.5 | 0.50 | 2.00 | 3.15 | 0.010 | 0.18 | |

| Min | 63.00 | 2.30 |

Applications of Customized CNC Machined Inconel

- Aerospace Industry

Precision components for aircraft and spacecraft, where durability and high performance are critical. Explore our range of CNC Machined Titanium and CNC High-Speed Steel Products for additional aerospace-grade options tailored to meet your aerospace industry requirements

- Chemical Processing

Components crafted for aggressive chemical environments, benefit from Inconel’s superior corrosion resistance. Discover our offerings in CNC Mumetal Nickel Sheets and Customized Hastelloy for further solutions designed to withstand harsh chemical environments.

- Oil and Gas

Precision parts for high-pressure and corrosive applications in the oil and gas industry, ensuring reliability in challenging conditions. Explore our range of Customized Duplex and Customized Super Duplex for additional options tailored to withstand the harsh conditions of the oil and gas sector.

Why Choose Our Customized CNC Machined Inconel

- Superior Corrosion Resistance

- High-Temperature Performance

- Tailored Precision

Advanced CNC Techniques for Complex Designs

Utilizing the latest CNC technology, Marine Techq crafts intricate and accurate Inconel parts that meet exacting tolerances. Our skilled machinists combine traditional craftsmanship with innovative techniques to deliver products that are not only effective but also consistently reliable.

Why Partner with Marine Techq for Inconel Machining?

- Expertise in Advanced Alloys: Our team has extensive experience working with high-performance alloys, ensuring top-quality machining of Inconel.

- Custom Solutions: We provide full-scale customization to adapt to any project requirement, from single prototypes to full production runs.

- Quality Assurance: Every Inconel component is rigorously inspected for quality and performance to ensure it meets your needs and our standards.