CNC Machining Titanium, Hastelloy, Gas, Oil, and Marine Products

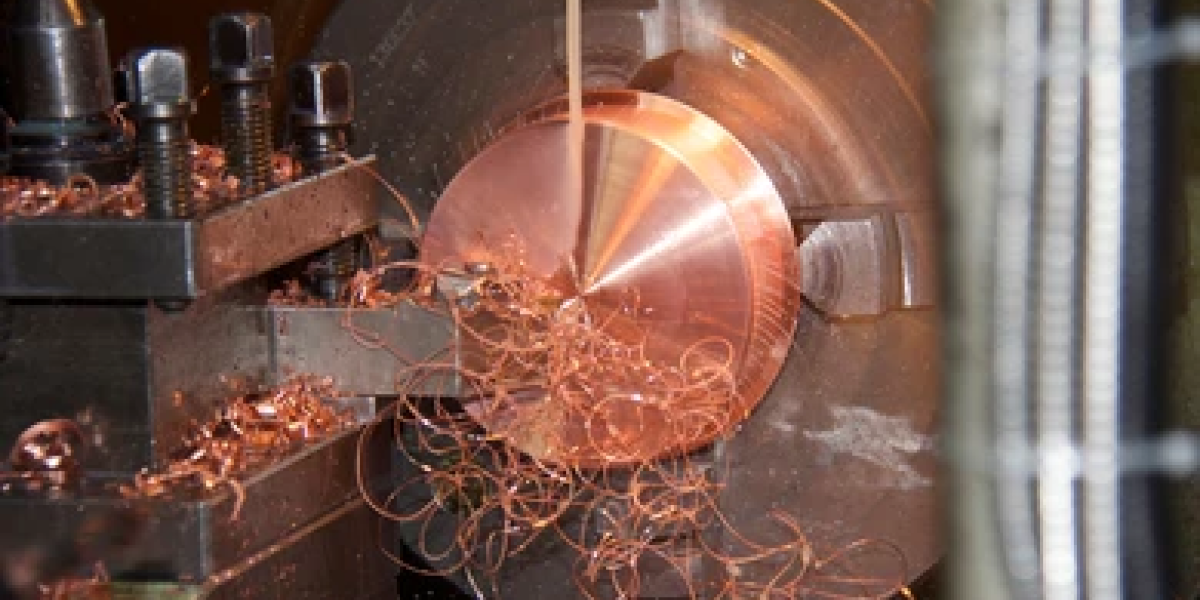

CNC (Computer Numerical Control) machining has revolutionized the way critical components are manufactured for industries like oil and gas, aerospace, marine, and chemical processing. By enabling precise and efficient production, CNC machining has become indispensable for creating durable and high-performance products from advanced materials like Inconel, Hastelloy, Titanium, and Copper Titanium.

In this FAQ-style blog, we’ll explore how CNC machining is impacting key industries, the materials involved, and the applications driving these advancements.

What is CNC Machining and Why is It Critical for Industrial Applications?

Key Benefits:

- Accuracy: Ensures dimensional precision for critical components.

- Efficiency: Reduces production time and material waste.

- Versatility: Can work with a variety of materials, from metals to composites.

CNC Machining for Oil and Gas Components

Why Is CNC Machining Essential for Oil and Gas Applications?

The oil and gas industry operates under extreme conditions, such as high pressure, corrosive environments, and fluctuating temperatures. CNC machining enables the creation of robust components that meet these demands.

Key Gas and Oil Components:

- Valves: Precisely machined to regulate flow and pressure.

- Compressors: High-performance components for gas transport.

- Pumps: Corrosion-resistant parts for fluid movement.

Applications:

- Gas Processing Plants: CNC-machined components ensure efficiency and reliability.

- Subsea Equipment: Durable materials like Inconel and Hastelloy withstand deep-sea pressures.

CNC Machining for Copper Titanium Hangers and Parts

What is Copper Titanium, and Why is CNC Machining Important?

Copper Titanium combines the strength of titanium with the conductivity of copper, making it ideal for structural and electrical applications. CNC machining allows for the customization of copper titanium hangers and parts, ensuring high precision and durability.

Applications of Copper Titanium Products:

- Marine Engineering: Corrosion-resistant hangers for ship components.

- Aerospace: Lightweight and strong parts for aircraft structures.

- Electrical Systems: High-conductivity hangers for power distribution.

Why Choose CNC for Custom Titanium Parts?

CNC Machined Hastelloy Components

What Makes Hastelloy a Preferred Material?

Hastelloy is a nickel-based alloy known for its exceptional resistance to corrosion and high temperatures, making it ideal for chemical and marine applications.

How CNC Machining Enhances Hastelloy Products:

- Customized Solutions: Tailors parts to specific needs, such as reactors or heat exchangers.

- Precision Machining: Maintains integrity under mechanical stress and corrosive conditions.

- Reduced Waste: Optimized processes minimize material loss.

Applications:

- Chemical Reactors: CNC-machined Hastelloy parts resist acids and oxidizing agents.

- Marine Equipment: Durable components for underwater operations.

CNC Machined Inconel for High-Performance Needs

Why is Inconel Ideal for CNC Machining?

Inconel, a nickel-chromium superalloy, offers outstanding resistance to extreme heat and corrosion. CNC machining enables the production of intricate Inconel components for critical systems.

Benefits of CNC Machined Inconel:

- Heat Resistance: Suitable for high-temperature environments, such as gas turbines.

- Corrosion Resistance: Ideal for marine and chemical processing systems.

- Longevity: Reduces maintenance and replacement costs.

Key Applications:

- Gas Turbines: Heat-resistant parts for efficient energy generation.

- Marine Propulsion Systems: Corrosion-proof components for long-term performance.

How Does CNC Machining Benefit the Marine Industry?

Marine environments are harsh and demand materials and components that can withstand corrosion, pressure, and wear. CNC machining ensures these components are reliable and long-lasting.

Marine-Specific Products:

- Propeller Shafts: High-strength shafts made from Inconel or Hastelloy.

- Seawater Pumps: Corrosion-resistant parts for consistent operation.

- Structural Hangers: Copper titanium hangers for marine frameworks.

Conclusion

CNC machining is transforming industries like oil and gas, marine engineering, and chemical processing by enabling the production of high-performance components from advanced materials like Inconel, Hastelloy, and Copper Titanium. With its ability to deliver precision, durability, and efficiency, CNC machining is paving the way for innovation in critical industrial applications.

Looking for precision CNC machining solutions for your next project? Contact us today to explore how our expertise can enhance your oil, gas, and marine systems with tailored, high-performance components.

FAQ's

CNC machining ensures that components like valves, pumps, and compressors meet the high precision and durability required for extreme conditions in oil and gas systems.

Hastelloy's exceptional resistance to corrosion and high temperatures makes it ideal for chemical reactors, heat exchangers, and marine equipment, especially in environments exposed to acids and seawater.

CNC machining allows for precise manufacturing of intricate Inconel parts that withstand high temperatures and corrosion, making them essential for gas turbines, marine propulsion, and aerospace engines.