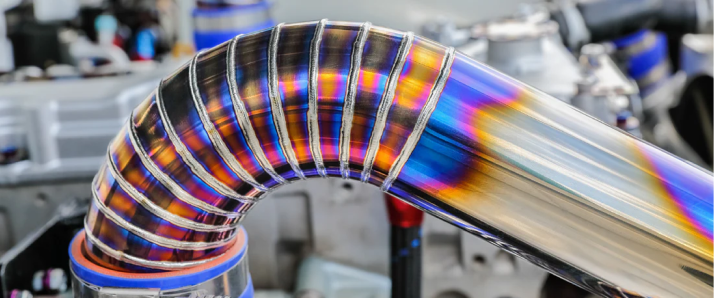

Special Titanium Welding

Need any Help?

Feel free to contact us any time. we will get back to you as soon as we can!

DOWNLOAD OUR BROCHURE

CONTACT US

At Marine Techq, we understand the unique demands placed on marine shafts. These critical components require exceptional strength, durability, and resistance to corrosion that standard materials simply can’t match. That’s why we offer specialized titanium welding services for marine shafts.

Why Titanium Welding for Marine Shafts?

Titanium offers several advantages over traditional materials for marine shafts:

Superior Corrosion Resistance:

Titanium is exceptionally resistant to saltwater corrosion, a major concern for any marine component.

High Strength-to-Weight Ratio:

Titanium is solid for its weight, allowing for lighter-weight shafts without sacrificing performance.

Excellent Fatigue Strength:

Titanium’s exceptional fatigue strength makes it ideal for these demanding applications.

Continue Reading on Similar Topics:

Our Titanium Welding Expertise

Marine Techq possesses the expertise and equipment necessary to perform high-quality titanium welds for your marine shafts. Our welders are certified and extensively trained in specialized titanium welding techniques, ensuring:

- Inert Gas Shielding:

We utilize advanced shielding techniques to prevent oxygen and nitrogen contamination during the welding process, which can significantly weaken the weld.

- Filler Metal Selection:

We select the appropriate titanium filler metal to match the specific properties of your marine shaft material.

- Precision Heat Control:

Titanium welding requires precise heat control to achieve optimal weld strength and prevent distortion. Our experienced welders ensure meticulous temperature management throughout the process.

- Post-Weld Treatment:

We offer various post-weld treatments, such as stress relief annealing, to further enhance the strength and longevity of your titanium welds.

Benefits of Choosing Marine Techq for Titanium Welding

- Enhanced Performance:

Our titanium welding expertise ensures your marine shafts possess the exceptional strength, corrosion resistance, and fatigue strength needed for optimal performance at sea.

- Extended Lifespan:

By utilizing titanium and our specialized welding techniques, you can expect a significantly longer service life from your marine shafts.

- Reduced Maintenance Costs:

The superior corrosion resistance of titanium translates to less frequent shaft replacements and lower overall maintenance costs.

- Improved Fuel Efficiency:

The lighter weight of titanium shafts can contribute to improved fuel economy for your vessel.

Difference in Titanium Welding

Marine Techq is at the forefront of providing specialized titanium welding services that meet the complex demands of modern engineering projects. Our expertise in handling titanium—a material known for its strength, lightweight properties, and corrosion resistance—ensures that we deliver superior welding solutions that stand the test of time.

Key Features of Our Titanium Welding Services:

- Advanced Techniques: We utilize state-of-the-art welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), to ensure high-quality joints and superior finish.

- Custom Fabrication: From design consultation to the final weld, our services are tailored to meet the specific needs of your project, ensuring perfect fit and function.

- High Corrosion Resistance: Titanium is ideal for harsh environments, offering unmatched resistance to corrosion, making it perfect for marine, aerospace, and industrial applications.

- Lightweight and Strong: Enhance the structural integrity of your projects without the weight burden, making titanium an excellent choice for efficiency and performance.

Why Choose Marine Techq for Titanium Welding?

- Expertise: Our certified welders have extensive experience and are trained in the latest techniques to handle the unique properties of titanium.

- Quality Commitment: We adhere to stringent quality control processes to ensure that every weld meets our high standards of excellence.

- Project Support: From initial concept to completion, our team offers comprehensive support and advice to ensure your project’s success.

FAQ

Which welding process is used for titanium?

At Marine Techq, we primarily utilize Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding, for joining titanium. This process provides the precise control and inert gas shielding necessary to achieve high-quality, contamination-free welds.

What is titanium welding called?

Titanium welding isn't referred to by a single, unique term. However, the most common process used at Marine Techq for welding titanium is Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding.

What is the Specialty of Titanium?

•Exceptional Corrosion Resistance: Titanium is remarkably resistant to saltwater corrosion, a major concern for marine components like shafts.

•High Strength-to-Weight Ratio: For its weight, titanium is incredibly strong, allowing for lighter shafts without compromising performance. This translates to potential fuel efficiency gains.

•Excellent Fatigue Strength: Marine shafts endure constant cyclic loading. Titanium's exceptional fatigue strength makes it ideal for these demanding applications. pen_spark

•High Strength-to-Weight Ratio: For its weight, titanium is incredibly strong, allowing for lighter shafts without compromising performance. This translates to potential fuel efficiency gains.

•Excellent Fatigue Strength: Marine shafts endure constant cyclic loading. Titanium's exceptional fatigue strength makes it ideal for these demanding applications. pen_spark

Why is titanium used in welding?

While titanium itself isn't always the material being welded, it's a valuable material for fabricating critical components like marine shafts due to the reasons mentioned above. Marine Techq employs specialized welding techniques to join titanium parts for these applications.